Motors:

Choice was between stepper motors and DC servo motors; I decided stepper motors would be easier to control. I ordered 3 stepper motors from AliExpress: link

I decided to use belts for converting rotational movement of the steppers to translational movement. They are faster, low noise, and cheaper than lead-screw used generally for this purpose. I found a nice site selling belts, gears and all kind of useful stuff: http://www.robotdigg.com/

Wednesday, January 20, 2016

Tuesday, January 5, 2016

Planning

The machine would have a fixed frame, as it offers more rigidity, having a table moving in X axis, a gantry moving on the Z axis and a tool holder moving on the gantry along the Y axis.

A rotating axis "A" axis could be added to rotate the tool or on the table, rotating the work-piece.

The frame:

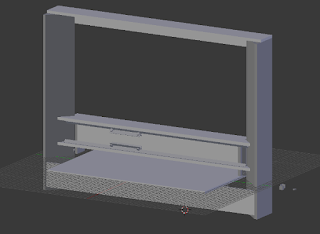

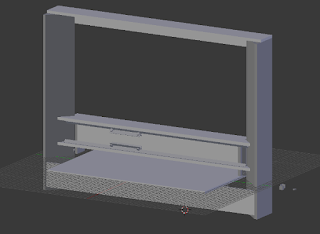

After some research I decided to build the machine out of "baltic birch" plywood. The sliding prismatic joint should be made by bearings on aluminium profiles. It should look something like this:

I found some discarded aluminium framing materials, I decided to make the frame out of that, as it confers more rigidity and more important it is not subjected to warping as the wood is and also I can use it as a basis for the prismatic joints as well.

A rotating axis "A" axis could be added to rotate the tool or on the table, rotating the work-piece.

The frame:

After some research I decided to build the machine out of "baltic birch" plywood. The sliding prismatic joint should be made by bearings on aluminium profiles. It should look something like this:

I found some discarded aluminium framing materials, I decided to make the frame out of that, as it confers more rigidity and more important it is not subjected to warping as the wood is and also I can use it as a basis for the prismatic joints as well.

Friday, January 1, 2016

Scope

While building prototypes of concept model lip wing aircraft, presented on aliptera.com website, I run into cutting by hand complex curved shapes for the wings and fuselage.

The work was tedious at least, the model didn't look very good and it took forever to make.

I reached the conclusion I need a CNC machine to do the complex shapes I want.

It needs to be able to cut foam in 3D, making complex shapes. For this I think a loop of nichrome wire of 1/4 -1/2 inch diameter would do nicely. To ensure rigidity of the loop some thicker gauge wire should be used.

I would like to use it also for cutting/engraving aluminum, wood, plexiglass.

Size: As big as possible. 4 x 3 x 3 ft would be nice.

The work was tedious at least, the model didn't look very good and it took forever to make.

I reached the conclusion I need a CNC machine to do the complex shapes I want.

It needs to be able to cut foam in 3D, making complex shapes. For this I think a loop of nichrome wire of 1/4 -1/2 inch diameter would do nicely. To ensure rigidity of the loop some thicker gauge wire should be used.

I would like to use it also for cutting/engraving aluminum, wood, plexiglass.

Size: As big as possible. 4 x 3 x 3 ft would be nice.

Subscribe to:

Posts (Atom)