Planning

The machine would have a fixed frame, as it offers more rigidity, having a table moving in X axis, a gantry moving on the Z axis and a tool holder moving on the gantry along the Y axis.

A rotating axis "A" axis could be added to rotate the tool or on the table, rotating the work-piece.

The frame:

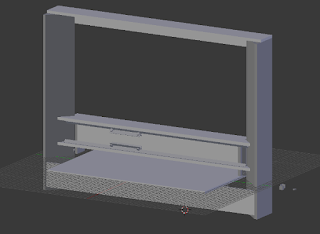

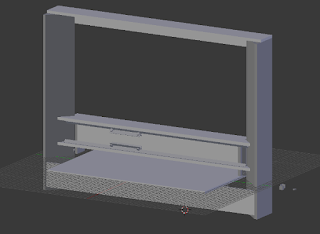

After some research I decided to build the machine out of "baltic birch" plywood. The sliding prismatic joint should be made by bearings on aluminium profiles. It should look something like this:

I found some discarded aluminium framing materials, I decided to make the frame out of that, as it confers more rigidity and more important it is not subjected to warping as the wood is and also I can use it as a basis for the prismatic joints as well.

A rotating axis "A" axis could be added to rotate the tool or on the table, rotating the work-piece.

The frame:

After some research I decided to build the machine out of "baltic birch" plywood. The sliding prismatic joint should be made by bearings on aluminium profiles. It should look something like this:

I found some discarded aluminium framing materials, I decided to make the frame out of that, as it confers more rigidity and more important it is not subjected to warping as the wood is and also I can use it as a basis for the prismatic joints as well.

Comments

Post a Comment